Sheet metal & drawn parts penetration

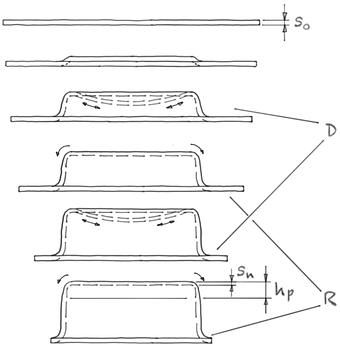

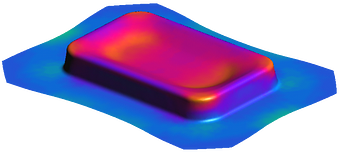

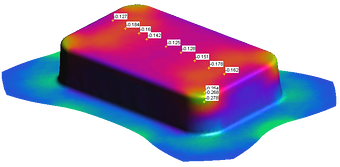

Penetration offers the possibility of adjusting solidifications in the drawn part base according to the specific functional requirements of the drawn part. Through repeated deformation and re-shaping of the floor area, material is redistributed from the bottom into the wall of the drawn part. This method increases material efficiency and thus increases the sustainability of the entire manufacturing process.145464748

During the deformation phases, the surface area of the floor area is increased, which leads to a reduction in the sheet thickness in this area. In the subsequent reformation phases, material flows from the ground into the wall of the drawn part. This redistribution of material means that a smaller starting board can be used while maintaining the same height of the drawn part.

After several penetrations, the soil is thinned out by between 12 and 18%. The insert board can be reduced in size accordingly.

The benefits of this procedure include:

- Solidification of the drawn part base up to the maximum possible expansion of the sheet metal

- Achieving a higher degree of forming

- Adjustable properties through variable parameters

- Significant material savings1

- Possibility of process control

- Improvement in shape retention

- Increasing process stability

- Reduction in reject rates

Converting an existing process to this procedure can be done in four steps:

- The potential of the process can be estimated through an initial feasibility and economic efficiency analysis.

- Determination of material savings and shape accuracy through comparative

- Making a test board on a test press. This test board is run through the existing process and the resulting properties can be evaluated.

- In the last step, the conversion of the process is planned and implemented.

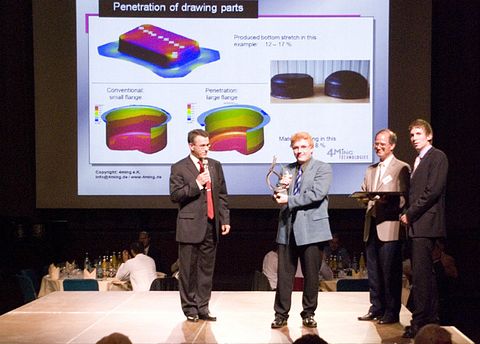

This technology was presented as part of the international conference "Recent developments in sheet metal forming 2008", organized by the IFU Stuttgart under the direction of Prof. Dr.-Ing. Liewald MBA, honored with the Science Prize.