Coefficients of Friction & Drawing Results

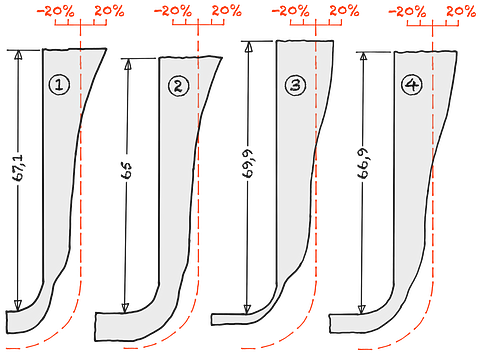

The course of the wall thickness and the height of the drawn part are significantly influenced by the coefficients of friction on the punch ( μSt ) and on the drawing die ( μZ ). A roughened drawing die can increase the achievable draw ratio β and the deep drawing safety.

With coated sheet metal on the drawing ring side, the material flows more efficiently during forming, which enables greater drawing limit ratios. With lubrication on the stamp side, e.g. with foil or stickers, the frame is stretched more, which leads to higher cups and thinning of the walls. However, this can also lead to premature contraction and tearing of the sheet metal, which is why lower limit drawing ratios are achieved.

Stamp-side coating is often preferred in order to avoid complex surface treatments. This is more complex, especially since the machining of the interior of hollow bodies is more complex.

In many cases, such as sinks, the inside of the drawn part is the visible surface, which is why a coating is necessary to avoid drawing marks and other surface damage caused by the tools.