Collar forming

In a pre-punched sheet metal (b), a punch (a), whose diameter ( dSt ) is larger than the original hole diameter ( d0 ), is pressed through the pre-hole. This increases the hole diameter and creates a collar in the finished part (c).819

Collary can be used in any form as storage, fixing and distancing elements on flat and shaped sheets, but also on pipes. Internal threads are often incorporated into the sheet metal openings. They therefore offer a variety of possible applications in industrial production.

| Widening | A | = | % | ||

| Degree of expansion | φA | = |

| Punch diameter | dSt | = | mm | |||

| Prehole diameter | d0 | = | mm |

During the forming process, the greatest stresses occur at the edge of the hole. If the expansion A is chosen too large, this can cause the collar to burst. Therefore, the expansion and the degree of expansion are crucial in determining the process limits. They represent a critical size that must be carefully controlled and tailored to the specific properties of the material in order to prevent excessive load and consequent damage to the material.

| Collar height | hK | = | mm |

| Constant | C | = | ||||

| Die diameter | dM | = | mm | |||

| Prehole diameter | d0 | = | mm | |||

| Sheet thickness | s0 | = | mm |

The achievable collar height is a key factor for the user. However, due to the large number of influencing factors, it is often difficult to estimate them precisely. The equation used to determine collar height is primarily applicable to narrow collars.

The factor C in this equation varies depending on the material: it is slightly larger for softer materials and slightly smaller for harder materials. These variations take into account the different properties of the materials and ensure that the equation produces accurate and reliable results.

| Stamp power | FSt | = | kN | ||

| Ejection force when collar forming | FK e | = | kN |

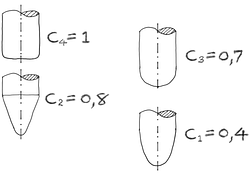

| Stamp factor | Ci | = | ||||

| Punch diameter | dSt | = | mm | |||

| Sheet thickness | s0 | = | mm | |||

| Prehole diameter | d0 | = | mm | |||

| Tensile strength | Rm | = | MPa |

| Collar height | hK | = | mm |

| Die diameter | dM | = | mm | |||

| Prehole diameter | d0 | = | mm | |||

| Die radius | rM | = | mm | |||

| Sheet thickness | s0 | = | mm |

| Collar height | hK | = | mm |

| Die diameter | dM | = | mm | |||

| Prehole diameter | d0 | = | mm |