Ironing

17

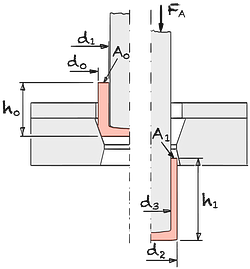

Fig. 1

Ironing

A0 peripheral area preferred A1 peripheral area second draw

d0 outside diameter preferred d1 inside diameter preferred d2 Outer diameter of second draw d3 Inner diameter of second draw h0 Height of preferred draw h1 Height of finished draw

During ironing, a deep-drawn cup is picked up by the punch and pulled completely through the drawing die. This results in a reduction in wall thickness while the thickness of the floor remains unchanged.

At the beginning of the drawing process, the ironing force is initially absorbed via the floor area. As soon as the frame is in contact with the punch , the friction between the punch and the frame partially contributes to the transmission of the drawing force.57

Eqn. 1

Eqn. 2

Eqn. 3

Eqn. 4

Eqn. 5

| Natural strain | φ | = | |||

| Cross-sectional strain | εA | = | % | ||

| Ironing force | FA | = | kN | ||

| Tearing force | FBR | = | kN | ||

| Work stripping | WA | = | kJ |

| Punch diameter | d0 | = | mm | |||

| d1 | = | mm | ||||

| d2 | = | mm | ||||

| d3 | = | mm | ||||

| Average work hardening | kfm | = | MPa | |||

| Tensile strength | Rm | = | MPa | |||

| Mean factor stretching | mA | = | ||||

| Height | h1 | = | mm |

Calc 1

Natural strain of ironing by ironing

The force required to tear the soil must always be greater than the ironing force. This therefore defines the limitations of the procedure.

When ironing , the average factor mA tends to be high and therefore close to 1.

Werkstoff | φzul |

|---|---|

Al99,5-99,8, AlMgSi1, AlMg 1, AlCuMg1 | 0.35 |

AlMg 2 | 0.35 |

Ms63 (CuZn37) | 0.45 |

Ck10 - Ck15, Cq22 - Cq35 | 0.45 |

42CrMo4, 16MnCr5, Cq45 | 0.35 |

Tbl. 1 Forming machine with 1 drawing ring12 | |

Higher natural strains can be achieved through intermediate annealing.

12

Tschätsch, H. / Praxis der Umformtechnik / Vieweg / Wiesbaden / 2003 / 7. Auflage

57

Lange, K. et al. / Fließpressen / Springer / Stuttgart / 2008 / 1. Auflage. Auflage