Embossing

Embossing is often used when processing large, irregularly shaped sheet metal parts. In this process, gutter-like depressions (such as beads54 ) or large-area embossed structures serve various purposes, which can be divided into usage and validity functions:

Include usage functions

- Increasing the section modulus

- Flow control of fluids

- Improvement of heat radiation behavior

- Improvement of structure-borne sound radiation behavior

- Mechanical stop

Include validity functions

- design

- Brand advertising

The hollow embossing represents a secondary mold element that is normally incorporated into the already preformed workpiece during the drawing or die bending process shortly before the end of the press ram stroke.

Various technical terms from the field of manufacturing processes, such as embossing, embossing, stretch forming, denting, denting, stretching, drawing and deepening, are often used synonymously. However, it should be noted that these terms each refer to specific aspects and techniques of metalworking.14

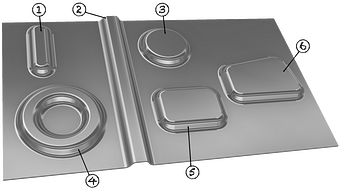

The desired utility function can be achieved by various types of embossing. The variants can differ significantly in terms of their area moment of inertia. For example, linear embossing (① & ②) always produces a direction-dependent, i.e. anisotropic, stiffening effect.

The following knowledge is an advantage for product developers and method planners:

- Simulation embossing

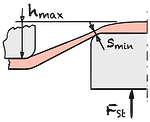

- Maximum embossing height hmax

- Maximum embossing force FSt & embossing work W

- Sheet metal thinning smin at the location of the thinnest point

- Increase in the moment of resistance due to the mass redistribution

This information allows for better control and optimization of the embossing process to achieve the desired properties of the end product.