Collar setting

14

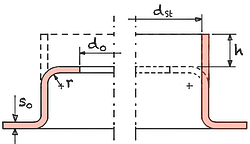

Fig. 1

collar setting

d0 hole diameter dSt punch diameter h collar height r punch radius s0 wall thickness

For the manufacture of high collars it is necessary to follow several steps. First of all, the material must be preferred. This is followed by punching, in which a hole is punched in the pre-drawn material. Finally, the remaining floor is put through. This process ensures the collar reaches the desired height while maintaining the structural integrity of the material.38

Eqn. 1

Eqn. 2

| Height | h | = | mm | ||

| Widening | A | = | % |

| Prehole diameter | d0 | = | mm | |||

| Punch diameter | dSt | = | mm | |||

| Radius | r | = | mm | |||

| Sheet thickness | s0 | = | mm |

Calc 1

Eqn. 3

| Prehole diameter | d0 | = | mm |

| Punch diameter | dSt | = | mm | |||

| Radius | r | = | mm | |||

| Height | h | = | mm | |||

| Sheet thickness | s0 | = | mm |

Calc 2

Prehole diameter d0

The force calculation for the punch force when collar setting is the same as for collar forming.

38

Romanowski / Handbuch der Stanzereitechnik / Technik Verlag Berlin / Berlin / 1968 / 4. Auflage