Forming-Analysis

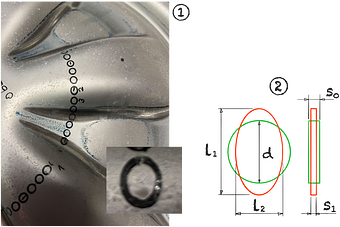

If circles with a constant diameter d are applied to a sheet of metal, the true strain can be calculated after forming. The main axes of the resulting ellipses are measured and divided by the initial diameter d.18 The logarithmic true strains are referred to as natural strains.

The law of constant volume results in a change in thickness. Therefore, by measuring the plane, the sheet thickness s1 can be determined non-destructively after forming. By delogarithmizing the corresponding strains ε are obtained.

| Natural strain | φ1 | = | |||

| φ2 | = | ||||

| φ3 | = | ||||

| Elongation | ε1 | = | % | ||

| ε2 | = | % | |||

| ε3 | = | % | |||

| Sheet thickness | s1 | = | mm |

| Length | l1 | = | mm | |||

| l2 | = | mm | ||||

| Circle diameter | d | = | mm | |||

| Sheet thickness | s0 | = | mm |

The measured true strains are to be entered in a forming limit diagram (FLD). The main change in shape φ1 forms the ordinate and the secondary change in shape φ2 forms the abscissa.18

The flow limit curve (FLC) shows the maximum formability limit of the material. The distance between the determined true strains and the FLC reflects the deep drawing safety.