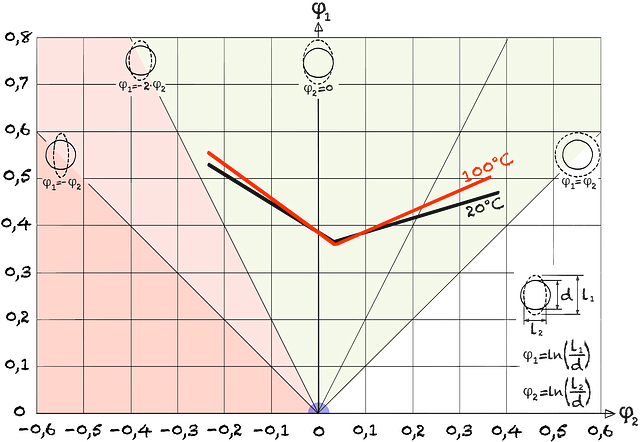

FLC Stainless Steel 1.4404

2.5

Fig. 1

Flow limit curve FLC stainless steel 1.4404 sheet thickness 1 mm22

At higher temperatures, martensite formation decreases. The flow limit curve shifts upwards.

Eqn. 1

Eqn. 2

Eqn. 3

| Natural strain | φ1 | = | |||

| φ2 | = | ||||

| φ3 | = | ||||

| Elongation | ε1 | = | % | ||

| ε2 | = | % | |||

| ε3 | = | % | |||

| Sheet thickness | s1 | = | mm |

| Length | l1 | = | mm | |||

| l2 | = | mm | ||||

| Circle diameter | d | = | mm | |||

| Sheet thickness | s0 | = | mm |

Calc 1

True strains to the circle element

22

Bleck, W. et.al. / EFB-Forschungsbericht Nr. 160 Bedeutung der Umformtemperatur und -geschwindigkeit bei der Blechumformung austenitischer Edelstähle / Europäische Forschungsgesellschaft für Blechverarbeitung e.V. / … / 2001 / …