Reshaping & Calibrating

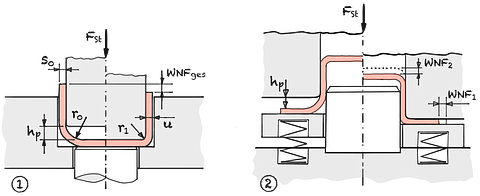

The deep-drawing process often requires larger die radii than desired for the final sheet metal part. It is therefore possible to reshape the radii in a separate operation. This process is also often referred to as lookup or calibration.

Since the component can get stuck in the mold gap, ejectors must be taken into account when reshaping.

Due to the constant volume and the changed alignment over smaller radii, there is a subsequent flow of the material. This can take on significant proportions. If this subsequent flow of the material is impeded by the tool, this leads to stresses, thinning of the sheet metal and increased stamping forces.

| Stamp power | FSt | = | kN | ||

| Embossing Height | hp | = | mm | ||

| Material flow | WNFges | ≤ | mm | ||

| Post-form work | WN | = | J |

| Correction value | K | = | ||||

| Punch circumference | lU | = | mm | |||

| Tensile strength | Rm | = | MPa | |||

| Initial radius | r0 | = | mm | |||

| Final radius | r1 | = | mm | |||

| Sheet thickness | s0 | = | mm | |||

| Embossing gap | u | = | mm |

The punch force FSt is the recommended minimum punch force. Higher forces bring only a small improvement in the dimensional deviation.21

Zugfestigkeit | Korrekturwert K |

|---|---|

Rm ≤ 500 MPa | 2.3 |

Rm > 500 MPa | 2.6 |

Tbl. 1 Correction value K | |

The correction value K for soft steels is Rm <500 MPa at 2.3. For higher-strength steel grades with an Rm > 500 MPa, a correction value of 2.6 is recommended.