Hydroforming of drawn parts

Hydroforming is ideal for producing deep-drawn parts with undercuts. This is a process in which the sheet metal is formed against a drawing die by a pressurized fluid.

Cup-shaped deep-drawn parts are brought into a tub shape by forming with fluid. In the case of small series, the deep-drawn goods are filled manually. In order to enable the formed deep-drawn part to be removed from the mold, the mold half must be divided into two.

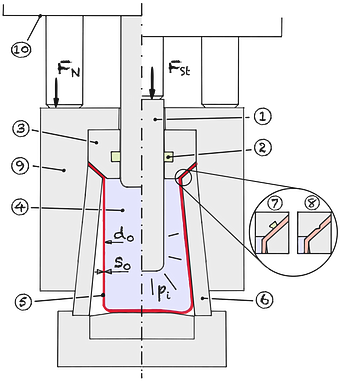

To generate an internal pressure pi, the deep-drawn product must be filled with fluid ④. The sealing holder ③ seals the fluid against the atmosphere. At the same time, the die holder ⑨ presses on the two drawing dies halves ⑥. The punch ① now penetrates the fluid ④, which increases the internal pressure until the metal rests against the forming dies ⑥. These must be divided into at least two parts to ensure that the undercut can be removed from the mold.

If a polymer seal ⑦ is used on the flange for sealing, material can flow from the flange into the cavity during forming, which makes the achievable bottom radii smaller. If, on the other hand, a serrated ring seal ⑧ is used, the sheet metal flow is impeded and larger bottom radii must be expected.

In order to perform this process on a single-acting press, a drawing cusion must be positioned between the hydroforming tool and the press.

The maximum internal pressure pi must not lead to a constriction of the deep-drawn part wall. To estimate the permissible internal pressure, the membrane equation can be used as a first approximation.*

| Maximum internal pressure | pi max | = | MPa |

| Sheet thickness | s0 | = | mm | |||

| Tensile strength | Rm | = | MPa | |||

| Punch diameter | d0 | = | mm |