Embossing force

The punch circumference lU , the wall thickness smin and the yield strength at the thinnest point are decisive for the calculation of the punch force in embossing.2514

For a conservative estimate, smin = s0 and kf = Rm is set.

The ejection force Fab is only relevant for high flank angles close to 90°.

| Stamp power | FSt | = | kN | ||

| Stripper force | Fab | = | kN | ||

| Work embossing | WH | = | kJ |

| Punch circumference | lU | = | mm | |||

| Minimal thickness | smin | = | mm | |||

| Average work hardening | kfm | = | MPa | |||

| Flank angle | α | = | ° | |||

| Clear Height | h | = | mm | |||

| Mean factor embossing | mH | = |

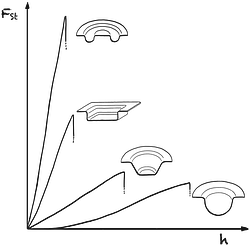

The force curves of different geometries are similar. It turns out that the mean factor mH is close to 0.5 for all forms.

In the case of channel-shaped beads, care must be taken to determine the punch circumference lU correctly. Both the rising bead flank and the descending bead flank must be taken into account when calculating the punch circumference.

The embossing force is not a function of the projected area of the stamp. However, if the hollow embossing is to be reshaped at top dead center (UT) in the sense of a straightening process, the determined embossing force must be increased in the same way as for die embossing.