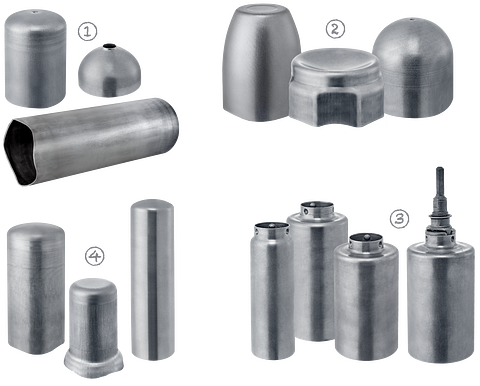

Range of parts

Multiple drawing enables the production of a large number of drawn part geometries. The following molds, among others, are produced on these machines today:

- Drafts pressure vessels , fire extinguishers, beer kegs, gas bottles , boilers

- Flange pulls container lids, beer kegs, gear covers

- Non-cylindrical trains air tanks , burial urns

- Detached trains Lid for container, reflector housing

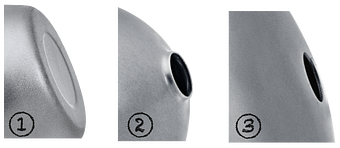

A common requirement is to create various secondary shapes on the bottom of the drawn part that have different functions:

Hollow embossing

These serve to stabilize the container and give it additional strength.

collar

Collars are used to introduce threads or to weld on fitting , for example to create a connection.

Perforations

Threaded connectors or other components can be integrated into the drawn part using holes.

The punching burr for holes can be oriented either from the inside to the outside or vice versa, depending on the application and the specific requirements.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.