Tolerances & process selection

"The cautious designer is always a friend of tight tolerances and ample sheet metal thicknesses. With reference to the structure of the device he has developed and the necessary precision of the working parts, he refuses to make concessions to refinement.

Very often it is necessary to completely change the previous design in order to refine the device and make it cheaper to produce."42

The connection between tolerance class and manufacturing costs is easy to see. The smaller the tolerance class selected, the higher the costs relating to process management, tool quality, quality assurance or the resulting reject rates.

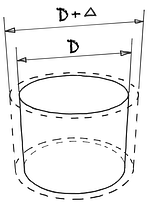

| Tolerance | Δ | = | μm |

| Nominal size | D | = | mm | |||

| Tolerance level | IT | = |

Example I A drawn part with a diameter of 300 mm is manufactured in tolerance class IT 12 (eg deep drawing). This results in a calculated basic tolerance of 525 μm. If the container is instead produced by ironing (IT9), the achievable basic tolerance is 132 μm.