4Ming Boost: High drawn parts on mechanical presses

The patented 4Ming® Boost translates the downward movement of the press into an upward movement of the drawing die, achieving more efficient and powerful forming. The lever mechanism reduces the press stroke, which means that the working capacity of the press is less utilized. This makes it possible to use mechanical presses for high deep drawings.2

Mechanical presses versus hydraulic presses

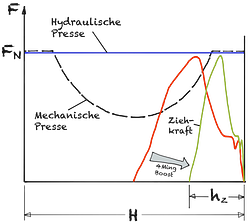

In a mechanical press, the force available on the ram varies with the ram travel depending on the kinematics of the drive (e.g. toggle lever or crank drive). In a mechanical press with a standard design, the nominal force FN of the press can only be used to 8% of the total stroke H.3

The drawing force when producing deep draws often overwhelms the force limit curve of the mechanical press, which is why hydraulic presses are predominantly used for such applications. By using 4Ming® Boost, the force curve is shortened, meaning that high deep drawings can now also be carried out on mechanical presses. Shortening the force curve reduces energy use by 50%.