Anisotropy

During the rolling process, thin sheet metal obtains a texture through grain orientation, which the mechanical properties become anisotropic (direction-dependent). This plays an important role in sheet metal forming.

A measure of the anisotropy of plastic properties of sheet metal materials is the r-value. It describes the so-called vertical or plastic anisotropy, the ratio of the deformation degrees in surface direction to the thickness direction.

The plastic anisotropies at angles of 0° and 90° to the rolling direction are calculated as follows:

Here, φl φb means the degrees of deformation in the longitudinal and width directions, φs the natural strain in the thickness direction. Numerical indices indicate the angle between the sample position and the rolling direction.

- r = 1 material isotropic, same true strain in width and thickness directions

- r > 1 true strain primarily in the width direction

- r < 1 true strain primarily in the thickness direction

To determine the average vertical anisotropy, an anisotropy value is also determined using a 45° sample. The mean vertical anisotropy is given by:

The mean vertical anisotropy rm is a measure of the unevenness. A good deep-drawing steel has an average vertical anisotropy value of rm ≥ 1.25.

Regarding spring back , it is recommended to use a low vertical anisotropy as this has a positive influence on stability.

The planar anisotropy Δris a measure of the unevenness:

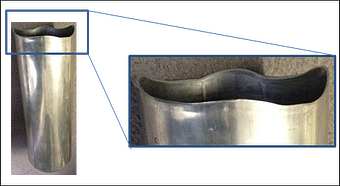

- Δr > 0 corners in 0° and 90° directions

- Δr ≤ 0 corner in 45° direction

Werkstoff | r0 | r45 | r90 | rm | Δr | s0 |

|---|---|---|---|---|---|---|

1.4016 | 0.78 | 0.6 | 1.5 | - | - | - |

1.4301 | 0.76 | 1.21 | 1.1 | 1.1 | -0.29 | 1 |

1.4541 | 0.6 | 1.3 | 1.08 | 1 | -0.5 | - |

Al 99,5 / G13 | 0.76 | 1.91 | 1.75 | 1.58 | -0.65 | 1 |

Al 99,5 / G9 | 0.92 | 0.68 | 1.07 | 0.84 | 0.32 | 1 |

Al 99,5 / W7 | 1.36 | 0.36 | 1.36 | 0.86 | 1 | 1 |

AlMg3 / G27 | 0.43 | 1.09 | 1.16 | 0.95 | -0.29 | 1 |

AlMg3 / W19 | 0.77 | 0.65 | 0.75 | 0.7 | 0.11 | 1.5 |

AlMg5Mn / W/27 | 0.67 | 0.97 | 0.76 | 0.84 | -0.25 | 0.8 |

AlSi1,2Mg0,4 / T4 | 0.77 | 0.59 | 0.75 | - | - | 1.2 |

BHZ 220 | 1.34 | 1.06 | 1.75 | 1.3 | 0.48 | 1 |

BHZ 300 | 1.12 | 0.98 | 1.42 | 1.14 | 0.33 | 1 |

DC 03 | 1.7 | 1.22 | 2.1 | 1.56 | 0.68 | 1 |

DC 04 | 1.86 | 1.44 | 2.23 | 1.75 | 0.62 | 0.8 |

ZStE 260 | 0.8 | 1 | 0.1 | 0.97 | -0.07 | 1 |

ZStE 420 | 0.91 | 1.47 | 1.17 | 1.26 | -0.433 | 1 |

Tbl. 1 Anisotropy of selected materials14151617 | ||||||