Stretch Forming Capability

1.5

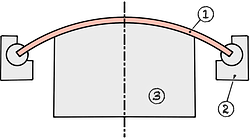

Stretch forming is a forming process in which the material is subjected to equal or unequal tensile forces in the two main directions of its surface.

Fig. 1

Stretch forming

① Sheet metal ② Clamping element ③ Punch

No clear statements can be made about the stretch forming capability of a sheet metal material from individual tensile test characteristics. Therefore, the stretching value S was determined statistically from over 60 combinations of the individual characteristics of the tensile test.14

Eqn. 1

| Stretching value | S | = |

| Tensile strength | Rm | = | MPa | |||

| Yield strength | Rp 0,2 | = | MPa | |||

| Smallest perpendicular anisotropy | rMin | = | ||||

| Mean strain hardening exponent | nm | = |

Calc 1

Stretching value S

With the help of the stretch forming value S, it is possible to assess the stretch forming capability of a sheet metal material:

S < 3 Low stretch forming capability

S > 3 S < 4 Medium stretch forming capability

S > 4 High stretch forming capability

Werkstoff | Zugfestigkeit Rm [MPa] | Streckgrenze Rp0,2 [MPa] | Kleinste Senkrechte Anisotropie rMin | Mittlerer Verfestigungs- exponent nm | Streckziehwert S |

|---|---|---|---|---|---|

St 14 | 292 | 176 | 1.438 | 0.216 | 4.8 |

1.4301 | 631 | 292 | 0.764 | 0.349 | 4 |

AlMg3 W19 | 218 | 108 | 0.434 | 0.153 | 3 |

Al 99,5 W7 | 72 | 26 | 0.362 | 0.253 | 3.7 |

Al 99,5 G9 | 74 | 44 | 0.675 | 0.173 | 3.2 |

Al 99,5 G13 | 126 | 124 | 0.757 | 0.045 | 2.6 |

AlMg3 G27 | 260 | 204 | 0.434 | 0.153 | 2.3 |

BHZ 300 | 447 | 374 | 0.976 | 0.176 | 3.3 |

CHLY 40 | 466 | 231 | 0.827 | 0.217 | 3.9 |

PHZ 26 | 471 | 225 | 0.722 | 0.224 | 3.8 |

ZStE 260 | 382 | 289 | 1.087 | 0.162 | 3.7 |

Tbl. 1 Characteristic values from tensile test14 | |||||

14

Doege, E.; Breidohr, B. / EFB-Forschungsbericht Nr. 35: Untersuchungen zum Tiefziehen von Teilen mit unebenen Bodenformen / Europäische Forschungsgesellschaft für Blechverarbeitung e. V. / Hannover / 1988 / …