Buckling of the cutting punch Normal conditions

12.5

Fig. 1

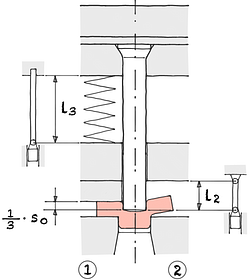

Bend punching die

① Spring-loaded guide plate ② Fixed guide plate l2 Free buckling length according to Euler case 2 l3 Free buckling length according to Euler case 3 s0 Sheet thickness

To calculate the buckling of cutting punches, Euler cases 2 and 3 are used. The length dimensions can be derived from the construction. It is assumed that the maximum moment of force is reached when the punching die has penetrated one third into the sheet metal.

The validity range for normal conditions includes a safety factor of 3. For unfavorable conditions, however, a safety factor of 5 is used. This takes into account additional uncertainties and potential risks to ensure that the punch functions reliably under these conditions.53

Eqn. 1

| maximum Compression Stress | σd zul | = | MPa |

| Young's modulus | E | = | GPa | |||

| Slenderness ratio | λ | = |

Calc 1

Allowable compressive stress for normal conditions 53

53

Klepzig, W. / Schneid- und Umformwerkzeuge für die Blechbearbeitung (Stanzwerkzeuge) / Hochschul-Lehrmaterial / Zwickau / 2010 / …