Cutting Clearance

12.4

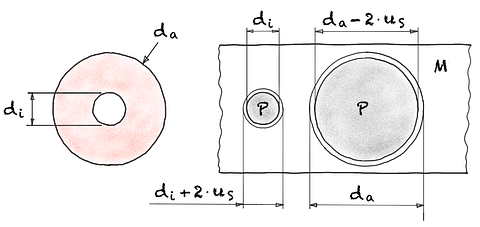

Fig. 1

Position cutting clearance

d i Inner shape d a Outer shape u S Cutting clearance M Cutting die P Cutting punch

When cutting out external shapes, the drawing die is given the nominal dimensions of the workpiece to be cut out. The punch must be twice the cutting gap smaller.

When cutting internal shapes, the punching die is given the nominal size of the workpiece, the dimensions of the drawing die are to be increased by twice the cutting gap.52

The quality of the cut surface of the workpieces and the tool life of the cutting tools is, among other things, significantly influenced by the size of the cutting gap u s ; this is the smallest distance between the cutting edges (of cutting plate and punch) that occurs during the cutting process. The size depends on:

- Material thickness and shear strength

- Surface quality of the free-form surfaces, whether filed or ground

- Inner shape of the breakthrough in the insert, whether conical or cylindrical25

52

… / Der Werkzeugbau / Europa Lehrmittel / … / 1986 / 9. Auflage

25

Semmlinger, E.; Hellwig, W. / Spanlose Fertigung: Schneiden-Biegen-Ziehen / Vieweg Fachbücher / … / 1990 / 4. Auflage