Non-cylindrical drawing

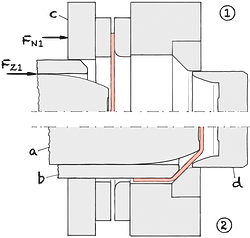

In this process, the sheet metal is first firmly clamped by the blank holder. The two-part drawing die then forms the sheet metal into a preferred shape, with the sheet metal bottom being conical in large areas. Here it is crucial to design the ground angle in such a way that no cup base fracture occurs.43

At this advanced stage of the deep-drawing process, the primary punch becomes the sheet metal holder for the second train. The punch for the finishing train then begins to form the sheet metal into the moving drawing die. During this process, the rotating drawing die exerts the necessary holding force to bring the sheet metal into the desired shape safely and efficiently.

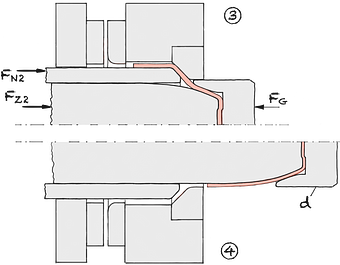

In the further steps of the process, the flangeless draw is then carried out. The sheet metal is further shaped by the punch for the finishing draw into the rotating drawing die. This process ensures that the sheet gets its final shape. It is important to note that throughout this process the correct balance between the applied force and the mechanical strength of the sheet metal must be maintained to ensure the best possible quality of the final deep-drawn part. 43