Wrinkles of the 2nd type

6.1

When forming non-cylindrical drawn parts, eg round or polygonal parts, the punch touches the sheet metal after the mold halves are closed. As the punch continues to descend, imaginary concentric annuli on the exit surface of the sheet are formed into annuli of smaller radius. The resulting geometric excess of material causes tangential compressive stresses.

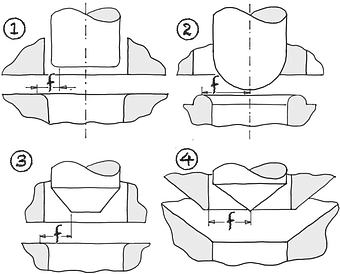

If the distance f between the back of the punch and the drawing radius is too great, extensive, tool-independent, i.e. free, forming can occur. In this case, the compressive stresses can lead to second-order folds. These are a particular type of deep drawing failure that can occur with non-cylindrical drawn parts.44

Fig. 1

Forming zones f with free, unbound areas

Fig. 2

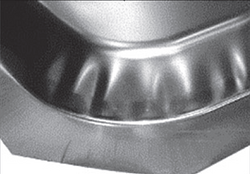

Wrinkling of the 2nd type5

5

Radonjic, Ranko / Kompensationsstrategien von Rückfederungseffekten beim Umformen von hochfesten Stahlbelchwerkstoffen / IFU Beiträge zur Umformtechnik Band Nr. 87 / … / 2020 / …

44

Oehler, G. / Gestaltung gezogener Blechteile / Cornelius / Hamburg / 1951 / …