Entry Angle

4.5

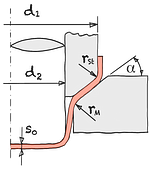

Fig. 1

Entry Angle

α Entry Angle d1 Predrawdiameter d2 Second Draw Diameter rM Die Radius rSt Punch Radius s0 Sheet Thickness

For larger drawing ratios, there is a straight section between the two deflection radii rM and rSt , which is conically inclined at an angle α to the horizontal to reduce the bending stress.

For different materials the entry angle is29

- Stainless steel α = 35°

- Aluminum α = 45°

If d1 /s0 > 100, the lead-in chamfer is α = 38°.

If d1 /s0 is determined between 50 and 100, the lead-in chamfer α = 45° is selected.28

The optimal entry angle α is given in27 as 45°.

29

Mönig, Elmar / Tiefziehen rotationssymmetrischer Blechformteile / unveröffentlicht / Bestwig / 2002 / …

28

Radtke, H. / Genaue Hohlkörper durch Blechumformen / expert Verlag / Esslingen / 1995 / 1. Auflage

27

Herold, G.; Kluge, M. / EFB-Forschungsbericht Nr. 61: Simulation des Formstempeltiefziehens im Weiterschlag / Europäische Forschungsgesellschaft für Blechverarbeitung e. V. / Hannover / 1994 / …