Optimal can

25.4.2

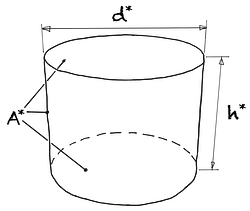

Fig. 1

Optimal container with base and lid

d* Optimum diameter h* Optimum height A* Optimum area Eqn. 1

Eqn. 2

Eqn. 3

Eqn. 4

| Optimal diameter | d* | = | mm | ||

| Optimal height | h* | = | mm | ||

| Optimal area | A* | = | mm2 | ||

| Height | href | = | mm | ||

| Surface | Aref | = | mm2 | ||

| Percent loss | q | = | % |

| Volume | Vi | = | L | |||

| Diameter | dref | = | mm |

Calc 1

Example 1 An optimal can with a beverage content of 0.9 l has an optimal diameter of 131 mm and a height of 66 mm. If the can diameter of a reference can is 100 mm instead, this results in a height of 115 mm with the same volume. The area loss of the reference can is -6.6%.

Example 2 A beer barrel with a capacity of 50 l has an optimal diameter of 503 mm and a height of 252 mm. If the reference diameter is 360 mm instead, this results in a height of 491 mm with the same volume. The barrel area loss is then -9.3%.