Penetrate & Multiple Drawing

Multiple drawing describes a process in which coaxially mounted drawing punches carry out several drawing stages in one operation. This process is characterized by its high productivity. It is used in the production of containers such as fire extinguishers, gas bottles, boilers, filter housings, funeral urns and others.

Through targeted movement kinematics in the first drawing section, an iterative thinning and solidification of the base of the drawn part is achieved. The material flows from the floor into the frame and the drawn part becomes higher. The insert board can thereby be significantly reduced in size. The drawing process, known as penetration , allows insert board reductions of up to 10%.

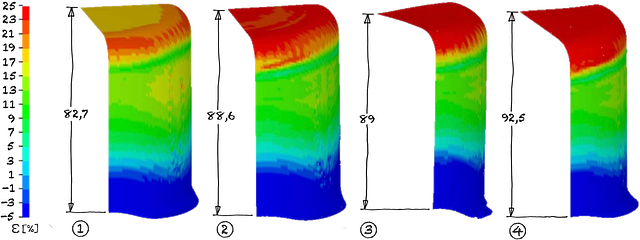

Depending on the penetration depth, different strain rates can be achieved per penetration. The number of penetrations ultimately influences the resulting soil strain, work hardening and the height of the drawn part.

In the first deep-drawing process, different strain rates can be generated by varying the penetration depth of the drawing punch. Combined with the number of penetrations, this allows for adjustable soil stretch. The drawn part undergoes local solidification in the base area, and part of the base mass flows into the frame. This either results in a higher drawn part or enables a significant reduction in the insert plate for a fixed drawn part height.

Dehnrate / Penetration | Höhe Ziehteil | max. Dehnung Boden | |

|---|---|---|---|

① | 0 % | 82,7 | 23 % |

② | 7 % | 88,6 | 30 % |

③ | 12 % | 89 | 33 % |

④ | 16 % | 92,6 | 49 % |

Tbl. 1 Drawn part heights and maximum elongation of the floor at different penetrations | |||