Short stroke penetration

8.3

The drawn part is manufactured in two consecutive steps:

- In the first stage of the work, the sheet metal is stretched and thinned by multiple penetrations in the base area, creating a frame. This reduces the initial sheet thickness and hardens the desired sheet metal zone to the required stress value.*

- In the second step, the preformed blank is passed on to the next station where it is deep-drawn into a hollow body.

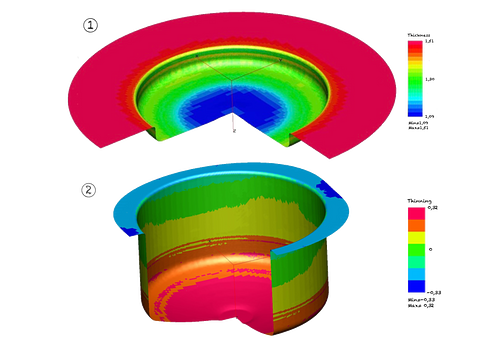

Fig. 1

Short-stroke penetrating beer keg

1) Penetrated circuit board 2) Subsequent deep drawing

The targeted strain hardening in the base area is particularly advantageous for the valve sleeve welded there. The static and dynamic strength characteristics experience a significant increase as a result.

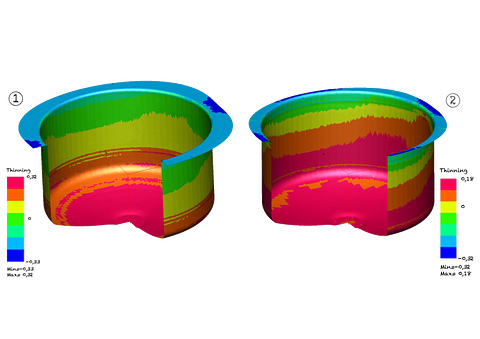

Fig. 2

Short-stroke penetration beer barrel

1) Beer keg with penetrated circuit board 2) Conventional beer keg

A direct comparison of a penetrated beer barrel with a traditionally manufactured one shows clear differences. Particularly noteworthy is the larger flange created by the redistribution of the sheet volume from the floor. In this case, the weight of the insert board can be reduced by 370 grams. At a current daily price of €2.5 per kilogram, this results in a cost saving of €0.925 per component.

*

Reitter, G. / Vorrichtung und Verfahren zum gezielten Beeinflussen des lokalen Blechdickenverlaufs und der lokalen Verfestigung einer Blechplatine / Patent Nr. DE102019005063A1 / … / 2019 / …