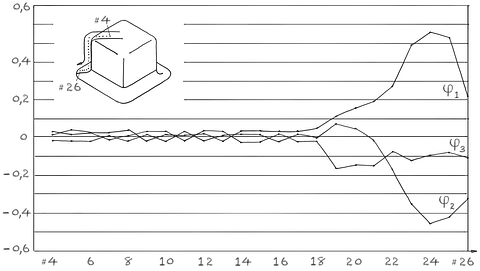

True strains

In classic deep drawing, the resulting stress conditions are often not sufficient to achieve a significant reduction in sheet thickness in the bottom area of the drawn part. The strength in the floor area usually corresponds to the strength of the starting material. This results in parts of the material remaining unused. In some cases, the low solidification in this area results in insufficient dimensional stability.

The stress conditions and the resulting elongation in the base of the drawn part depend on various parameters:

Geometric parameters:

- Shape of the drawn part base (flat, hemispherical, dished base…)

- Punch corner radius

- Die radius

Process parameters

- Sheet metal holder force

- Die radius

- temperature

- friction conditions

- lubrication

- Forming history

- Condition of wear

Material parameters

- Planar and vertical anisotropy

- Yield strength and tensile strength

- Flow curve , among others

In particular, the process and material parameters can vary significantly during the manufacturing process. It is therefore important to note that the achievable expansion values in the bottom of the drawn part are not constant and can change significantly during the course of the process.