4Ming Curve

The 4Ming curve we developed, based on the mathematical superellipse (lame curve), optimizes the deep drawing process by avoiding typical curvature jumps at the drawing edge inlet and outlet. This geometric adjustment leads to an even stress distribution and eliminates local stress concentrations that occur with the traditional drawing radius.

In practical applications, such as the forming of a stainless steel container, a significantly higher draw ratio could be achieved while reducing the required drawing force and allowing the use of lubricants with lower shear strength.

The uniform stress distribution leads to a significant reduction in the wear mechanisms of adhesion and abrasion. This is particularly interesting for tool materials with low compressive strength (e.g. Zamak).

We have produced several deep-drawing tools with the 4Ming curve. In summary, we can demonstrate the following advantages:

- Increasing the draw ratio

- Reduction of punch force

- Reduced damage to the drawing curve

- Improved friction conditions

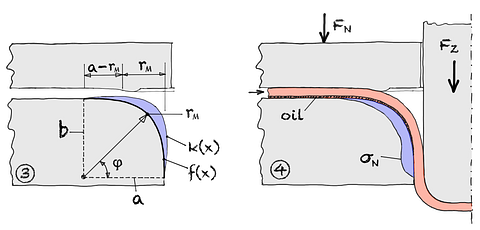

Stress distribution at the classic drawing radius

Normal stress maxima σN occur at the drawing edge inlet and outlet due to the geometric curvature jumps. These lead to a local concentration of the normal stresses σN as a result of the bending and re-bending moments. The high normal stresses cause lubricant to build up in front of the forming zone and be squeezed out, which makes the use of oils with high shear strength necessary (see Stribeck curve ).

4Ming Curve

The 4Ming curve we developed is based on the so-called superellipse (mathematically: Lame curve f(x) ). This avoids the typical curvature jumps at the drawing edge inlet and outlet. The curvature k(x) reaches a maximum at a defined point, with the minimum curvature radius rmin corresponding exactly to the classic drawing radius rm.

The typical squeezing out of oil at the drawing ring inlet is prevented. Oils with low shear strength can be used. Higher drawing ratios can be achieved and typical signs of wear on the tool or sheet metal are reduced.

Superellipse

The superellipse is a geometric figure that is an extension of the ellipse and is defined by equation 1. In this equation, a, b and n are the main parameters that determine the shape and extent of the superellipse. The parameter a describes the semi-axis along the x-axis, while b indicates the semi-axis along the y-axis. The parameter n affects the roundness of the curves, with n = 2 giving an ellipse, while larger values of n result in sharper corners and smaller values result in softer, more circle-like shapes. The superellipse is versatile in design and finds applications in areas such as architecture and industrial design.

The curvature k(x) of the superellipse begins and ends at 0, in between there is a maximum max( k(x) ). k(x) can be derived algebraically using the following relationship:

The maximum curvature max( k(x) ) is obtained by setting the derivative of k(x) equal to zero. This equation 3 is transcendental and cannot be solved for x. A numerical approximation method, the golden ratio method, is used to determine max( k(x) ).

Examples