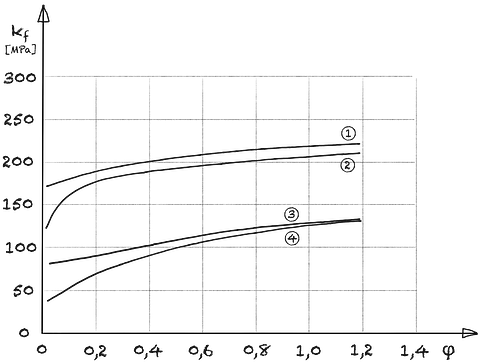

Flow Curve Al 99.5

1.3.5

Fig. 1

Flow curves13

① AlMgSi T64 ② AlMgSi O ③ Al 99.5 T64 ④ Al99.5 O kf cold flow strength φ natural strain

Eqn. 1

Eqn. 2

| Yield stress | kf | = | MPa | ||

| Average work hardening | kfm | = | MPa |

| Natural strain | φ | = | ||||

| Natural strain | φ1 | = | ||||

| Natural strain | φ2 | = |

Calc 1

Flow curve Al 99.5 T64, ③13

Eqn. 3

Eqn. 4

| Yield stress | kf | = | MPa | ||

| Average work hardening | kfm | = | MPa |

| Natural strain | φ | = | ||||

| Natural strain | φ1 | = | ||||

| Natural strain | φ2 | = |

Calc 2

Flow curve Al 99.5 O, ④ soft annealed13

13

Kugler, H. / Umformtechnik / Carl Hanser Verlag / München / 2009 / …