Free bending

16.4

In contrast to die or stamping bending, in which the workpiece is pressed into the tool with high pressure until it rests, the tools used in free bending only function as a means of transferring forces or bending moments to the workpiece.

The dimensional accuracy of the free bending is rather unsatisfactory compared to the precision of the stamping with a V-die. Fluctuations in spring back and other disturbing influences such as deviations in wall thickness have a relatively strong effect on the bend angle and bend radius.*

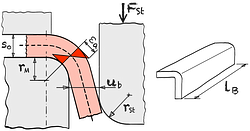

Fig. 1

Free bending*

lB bending length εa elongation outer fiber rM die radius rSt punch radius s0 sheet sheet thickness ub bending gap

Eqn. 1

Eqn. 2

Eqn. 3

Eqn. 4

Eqn. 5

| Max. punch force | FSt max | = | kN | ||

| Coefficient | ξ | = | |||

| Medium natural strain | φm | = | |||

| Bending factor | c | = |

| Die radius | rM | = | mm | |||

| Punch radius | rSt | = | mm | |||

| Sheet thickness | s0 | = | mm | |||

| Bending gap | ub | = | mm | |||

| Bending length | lB | = | mm | |||

| Average work hardening | kfm | = | MPa | |||

| Coefficient of friction | μ | = |

Calc 1

bending force

The tensile strength Rm can be used as an approximation for kfm.

By using a flow curve and the mean degree of deformation φm

more precise values for kfm can be determined.

*

Siegert, K. / Blechumformung / Springer Vieweg / Berlin / 2015 / …

*

Kluge, Siegfried / Prozesse der Blechumformung / Carl Hanser Verlag / München / 2020 / …