Hat profile bending

16.8

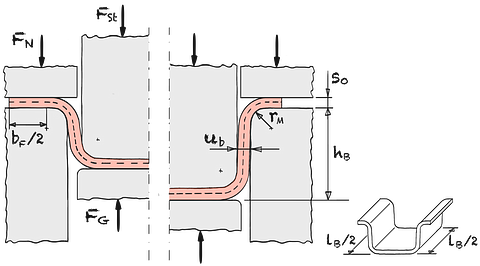

When bending a hat profile, a flat sheet metal blank is drawn into the bending die over die radius using a bending punch. A blankholder prevents the flanges from standing up. The frictional forces between the drawing die, blankholder and workpiece flange contribute to improved dimensional accuracy of the frame and base.

Fig. 1

Hat profile bending21

bF Flange width FG Counterholder force FN Blankholderforce FSt Punch force hB Bending height lB Bending length rM Die radius ub Bending gap s0 Wall thickness Eqn. 1

Eqn. 2

Eqn. 3

Eqn. 4

Eqn. 5

| Max. punch force | FSt max | ≥ | kN | ||

| Min. blankholderforce | FN min. | ≥ | kN | ||

| Backstop force | FG | = | kN | ||

| Bending factor | c | = | |||

| Bending work | WB | = | J |

| Coefficient of friction | μ | = | ||||

| Sheet thickness | s0 | = | mm | |||

| Bending length | lB | = | mm | |||

| Average work hardening | kfm | = | MPa | |||

| Die radius | rM | = | mm | |||

| Flange width | bF | = | mm | |||

| Mean factor bending | mB | = | ||||

| Bend height | hB | = | mm |

Calc 1

Stamping force hat profile bending

The tensile strength Rm can be used in a simplified form for kfm.

Since the sheet is guided over the die radii, one should assume slightly higher coefficients of friction μ.

21

Kluge, Siegfried / Prozesse der Blechumformung / Carl Hanser Verlag / München / 2020 / …