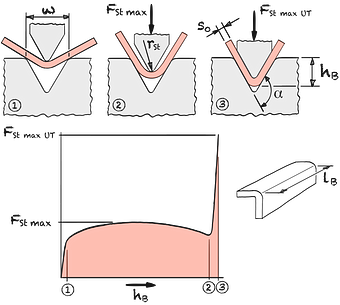

V-Bending

① At the beginning the strip bends elastically. In this phase the bending line corresponds to a cubic parabola.

② As soon as the bending stress on the edge fibers exceeds the elastic limit, flow occurs in these areas. The permanent deformations begin in the middle of the strip length, where the bending moment is greatest, and continue towards the contact points on the die. After the legs are in contact with the die, free bending ends.

③ Until the form fit is complete, the strip must on the one hand be curved around the stamp rounding, and on the other hand the legs of the angle piece that have experienced unintentional bending must be straightened again using a straightening bending process. This is also known as counter-embossing or post-forming.569