U-Bending & Die Stamping

16.5

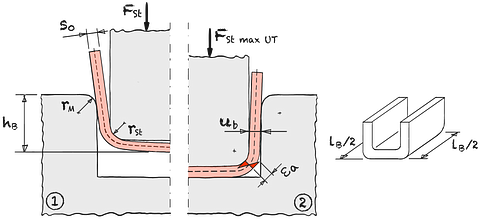

Fig. 1

U-bending*

lB Bending length εa Elongation of outer fiber FSt Punch force F St max UT Maximum punch force Bottom dead center rM Die radius rSt Punch radius ub Bending gap s0 Wall thickness

The conditions for U-die bending correspond to free bending with twice the bending length b. At bottom dead center (BDC), the punch hits hard and the process switches to stamping. A higher embossing force FSt max UT is then required to ensure the flatness of the workpiece base.

Eqn. 1

Eqn. 2

Eqn. 3

Eqn. 4

Eqn. 5

Eqn. 6

Eqn. 7

| Max. punch force | FSt max | = | kN | ||

| Maximum punch force UT | FSt max UT | > | kN | ||

| Coefficient | ξ | = | |||

| Medium natural strain | φm | = | |||

| Bending factor | c | = | |||

| Bending work | WB | = | J |

| Die radius | rM | = | mm | |||

| Punch radius | rSt | = | mm | |||

| Sheet thickness | s0 | = | mm | |||

| Bending gap | ub | = | mm | |||

| Bending length | lB | = | mm | |||

| Average work hardening | kfm | = | MPa | |||

| Coefficient of friction | μ | = | ||||

| Mean factor bending | mB | = | ||||

| Bend height | hB | = | mm |

Calc 1

U-Bending & Die Stamping

The tensile strength Rm can be used as an approximation for kfm.

By using a flow curve and the mean degree of deformation φm

more precise values for kfm can be determined.

*

Kluge, Siegfried / Prozesse der Blechumformung / Carl Hanser Verlag / München / 2020 / …