True strain bending & bending factors

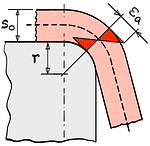

The true strain during the bending process results in an elastic-plastic stress in the bending zone. In this area, the outer zone of the material is stretched ( εa ) while the inner zone is compressed ( εi ).

In order to calculate the maximum drawing forces ( FS max ) during the bending process, it is helpful to know the mean natural strain. The mean natural strain is a measure of the amount of plastic deformation that the material experiences during the bending process.

This information is particularly useful when calculating the force required to bend, as it helps to better understand the stress on the material and the force required to produce the desired shape.

| Medium natural strain | φm | = | |||

| Bending factor | c | = |

| Radius | r | = | mm | |||

| Sheet thickness | s0 | = | mm |

The average natural strain φm is used in the flow curve to determine the average cold flow strength kfm. In this way, a more accurate estimate of the maximum pull forces can be obtained.

The maximum strains εa at the edges of the bending zone can lead to the formation of cracks and ultimately to the failure of the material. Therefore, the empirically determined minimum bending factor cmin for the selected lightweight materials should not be undershot.

This factor indicates the minimum acceptable elongation before cracking begins and is therefore critical to ensuring the structural integrity of the bent part. It is important that this factor is considered at the design stage to avoid premature failures and potential safety issues.

Werkstoff | Biegefaktor cmin |

|---|---|

Tiefziehblech, weich | 0.3 |

Höherfestes Stahlblech, Re = 350...500 MPa | 0.5 |

Höherfestes Stahlblech, Re > 500...650 MPa | 1 |

Höherfestes Stahlblech, Re > 650...800 MPa | 1.5 |

Höherfestes Stahlblech, Re > 800 MPa | 2 |

Austenitisches Stahlblech | 0.5 |

AlMg3 weich | 1 |

AlMg3 Halbhart | 1.3 |

AlMgSi1 weich | 1.2 |

AlMgS1 halbhart | 2.5 |

Tbl. 1 Minimum rounding factors cmin | |