Bending force I

16.7.1

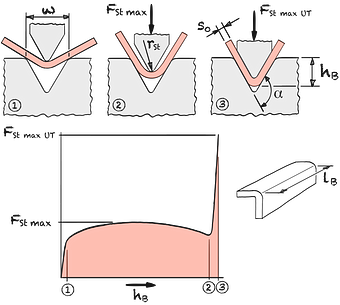

Fig. 1

V-die bending ① ② & embossing ③

α Bending angle FSt Punch force hB Bending height lB Bending length s0 Sheet thickness w Drawing width

Eqn. 1

Eqn. 2

| Max. punch force | FSt max | = | kN | ||

| Bending work | WB | = | J |

| Tensile strength | Rm | = | MPa | |||

| Sheet thickness | s0 | = | mm | |||

| Draw distance | w | = | mm | |||

| Bending length | lB | = | mm | |||

| Bend height | hB | = | mm | |||

| Mean factor bending | mB | = |

Calc 1

Maximum force FSt max die bending according to Oehler

Similar to deep drawing, the mean factors are between 0.6...0.9.

For steel sheets in the thickness range 0.5mm ≤ s0 ≤ 10mm and with 5 ≤ w / s0 ≤ 20 and w / rst ≥ 5, this relationship yielded results that corresponded well with experimental findings.19

Material parameters eg from the table for sample materials.

19

Lange / Umformtechnik Blechbearbeitung / Springer Verlag / Berlin / 1990 / 2. Auflage