Bending force II

16.7.2

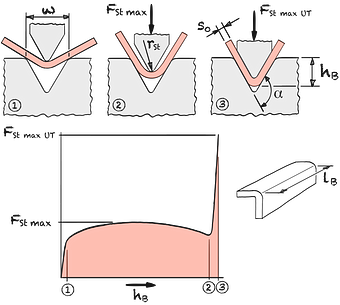

Fig. 1

V-die bending ① ② & embossing ③

α Bending angle FSt Punch force hB Bending height lB Bending length s0 Sheet thickness w Drawing width

Eqn. 1

Eqn. 2

| Max. punch force | FSt max | = | kN | ||

| Bending work | WB | = | J |

| Bending length | lB | = | mm | |||

| Die width | w | = | mm | |||

| Sheet thickness | s0 | = | mm | |||

| Tensile strength | Rm | = | MPa | |||

| Yield strength | Rp 0,2 | = | MPa | |||

| Uniform elongation | Agl | = | % | |||

| Bend height | hB | = | mm | |||

| Mean factor bending | mB | = |

Calc 1

Maximum force FSt max according to Zünkler56

Similar to deep drawing, the mean factors are between 0.6...0.9.

The calculation is to be applied to bending angles α ≥ 54°.

The advantage of this calculation is that the material properties yield point, tensile strength and uniform elongation, which have a special influence on the bending behavior, are taken into account.56

Material parameters eg from the table for sample materials.

14

Doege, E.; Breidohr, B. / EFB-Forschungsbericht Nr. 35: Untersuchungen zum Tiefziehen von Teilen mit unebenen Bodenformen / Europäische Forschungsgesellschaft für Blechverarbeitung e. V. / Hannover / 1988 / …

56

Zünkler, B. / Rechnerische WErfassung der Vorgänge beim Biegen im V-förmigen Gesenk / TH Stuttgart / Stuttgart / 1966 / …