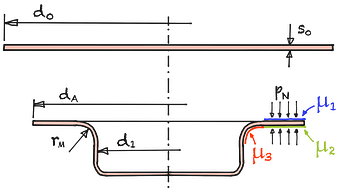

Blankholder Pressure

Precise adjustment of blank holder pressure, also known as blank or blank holders, is critical to successfully drawing a part. Excessive blankholder pressure can excessively decelerate the sheet metal, which can cause cracking when flowing around the draw radius. Too low blankholder pressure can cause wrinkling, referred to as first-order wrinkling, in the sheet entry zone (between the outer flange edge and the draw radius).

In contrast, there are second-order creases that can form below the drawing edge up to the punch radius. Excessive draw width (clearance) or a non-cylindrical punch shape is often responsible for this. The blankholder pressure can have a positive effect on the formation of second-order wrinkles, especially if the sheet metal has a high vertical anisotropy.

| Blankholder Pressur | pn | = | MPa |

| Draw ratio | β0 | = | ||||

| Diameter punch | d1 | = | mm | |||

| Sheet thickness | s0 | = | mm | |||

| Tensile strength | Rm | = | MPa |

The equation applies to the friction partners steel on steel with drawing oil and mixed friction. The calculated blankholder pressure can be increased by a factor of 4 by using double-sided drawing foil.13