The maximum achievable draw ratio ßnmax in the second draw, similar to the limiting drawing ratio in the first draw, is characterized by the fact that material failure due to bottom cracks is just avoided. Material failure occurs when the required drawing force FZ exceeds the maximum drawing force FBR that can be transmitted by the frame of the drawn part. In the best case, the sheet metal tears at the transition between the punch radius and the frame , since the cross-section is smallest here. The calculation of the tearing force at the bottom when second draw is carried out analogously to the determination of the tearing force at the bottom in the first pull.

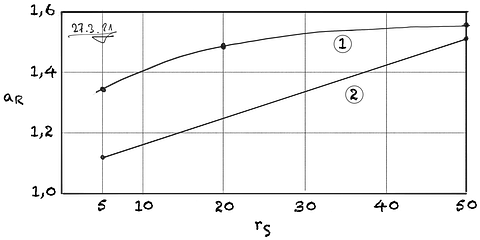

The tear off factor aR takes into account the wall thickness and yield stress that actually occur at the point of the crack.1927